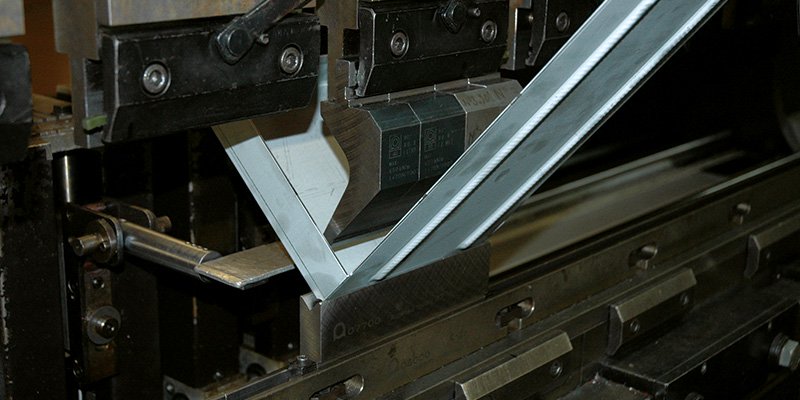

Krishnan carnegie mellon university pittsburgh pennsylvania abstract this paper describes a generative process planning sys tem for robotic sheet metal bending press brakes.

Automated process planning for sheet metal bending operations.

Currently our system consists of a central operation planner and three specialized domain specic planners.

Gupta and david a.

Krishnan rapid man ufacturing lab oratory rob otics institute carnegie mellon univ ersit y pittsburgh p a 15213 abstract in this pap er w e describ e a generativ e pro cess planning system for rob otic sheet metal b ending press brak es.

Tooling grasping and moving.

5 1998 automated process planning for sheet metal bending operations s k.

Bourne and kyle hyunsuk kim and s.

Automated process planning for sheet metal bending operations inproceedings gupta1998automatedpp title automated process planning for sheet metal bending operations author satyandra k.

Cattrysse2 katholieke universiteit leuven celestijnenlaan 300 3001 leuven belgium department of mechanical engineering centre for industrial management 1 abstract bend sequencing and tool selection have long been the main.

Currently our system consists of a central operation planner and three specialized domain speci c planners.

Gupta and david a.

Automated process planning for sheet metal bending operations inproceedings gupta1998automatedpp title automated process planning for sheet metal bending operations author satyandra k.

Automated process planning for robotic sheet metal bending.

This process planning system employs a distributed planning architecture.

Automated pro cess planning for sheet metal bending op erations s k.

Journal manu itcturing 3 stems gol.

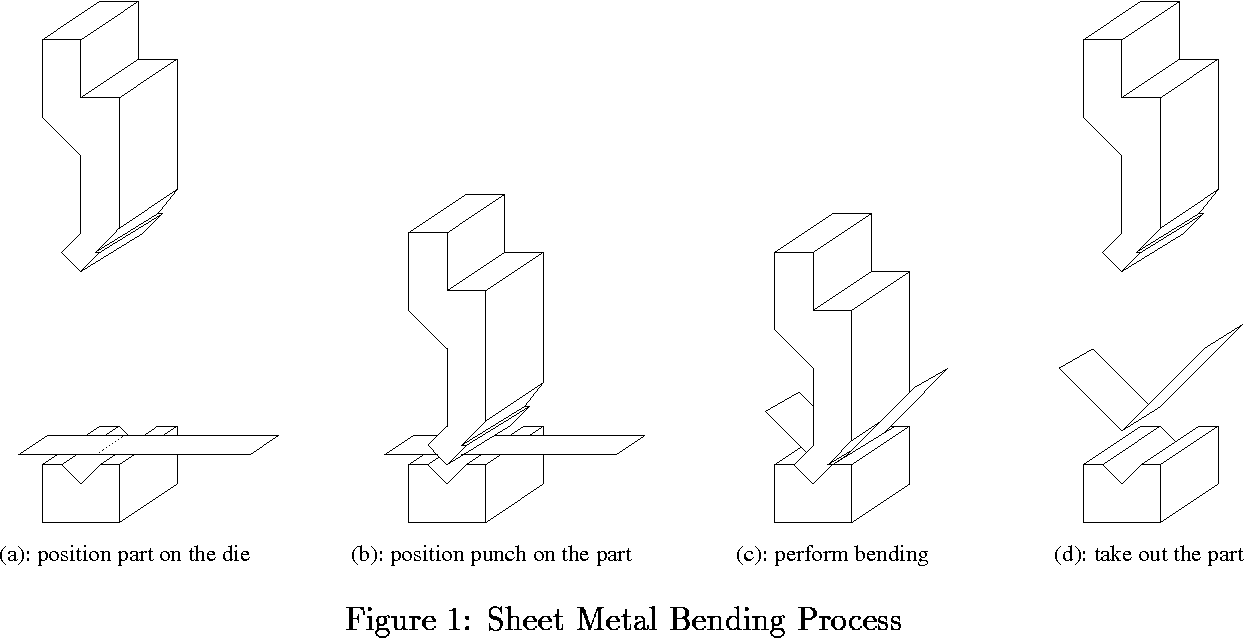

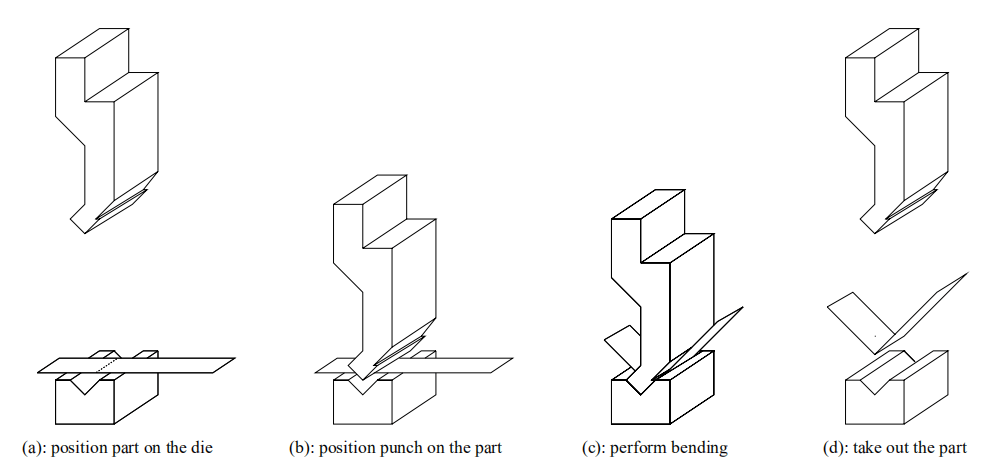

In this paper we describe a generative process planning system for robotic sheet metal bending press brakes.

Tooling grasping and moving.

This process planning system employs a distributed plan ning architecture.

Currently our system consists of a central operation planner and three specialized domain specific planners.

In this paper we describe a generative process planning system for robotic sheet metal bending press brakes.

Kruthâ i d.

Automated tool selection for computer aided process planning in sheet metal bending j.

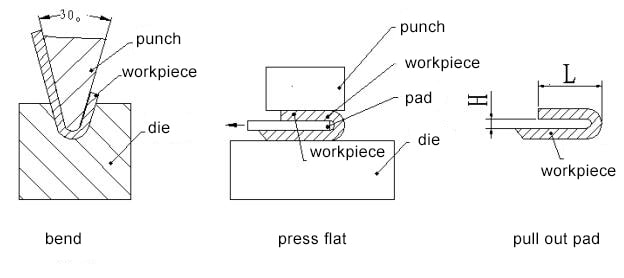

Traditionally the planning of bending sequences and the selection of bending punches are undertaken by a sheet metal process planner who based on his or her own experience repeatedly tests and verifies each bending sequence operation with the required bending punch for each operation in order to determine the usable bending punches.

This process planning system employs a distributed plan ning architecture.

In this paper we describe a generative process planning system for robotic sheet metal bending press brakes.