Many racing organizations will specify the minimum acceptable gauge for sheet metal in critical applications such as firewalls and protective enclosures.

Auto sheet metal gauge flux core.

The settings for flux core wire and non ferrous metals will be completely different.

When doing old car restorations sometimes its simpler to replace an entire panel instead of trying to straighten it or repair rust spots.

Remember that you re always trading off weight against strength when choosing a gauge of sheetmetal to use.

For sheet metal i use ine welding wire and it is just as good as their flux cored wire if you want you can grab one here.

For many welding applications like vertical up welding flat welding welding over galvanized or welding hard to weld steels a flux cored wire can do it better and faster.

Thanks for any info.

I m practicing up on my mig and am trying to determine settings using er70 6s and c25.

Flux core wires are compatible with a large variety of metals that includes nickel alloys stainless steel low alloy steel mild steel etc.

Although gas metal arc welding gmaw with a solid mild steel wire is popular easy to.

What thickness or gauge is standard automotive sheetmetal on american vehicles such as a door skin or fender skin.

A flux cored wire is optimized to obtain performance not possible with a solid wire.

When welding mild steel a good rule of thumb is to set the amperage level at 1 amp for every 0 001 of thickness.

So if you are welding 12 gauge mild steel with a thickness of 0 100 you would set the machine at 100 amps.

Whether you re working on a classic american car from 1957 or a truck made as recently as 2007 eastwood has sheet metal to help you fix it.

Beginner welders find that using flux core is one of the best methods to start their welding jobs and experienced welders find it convenient since they do not need to use gas.

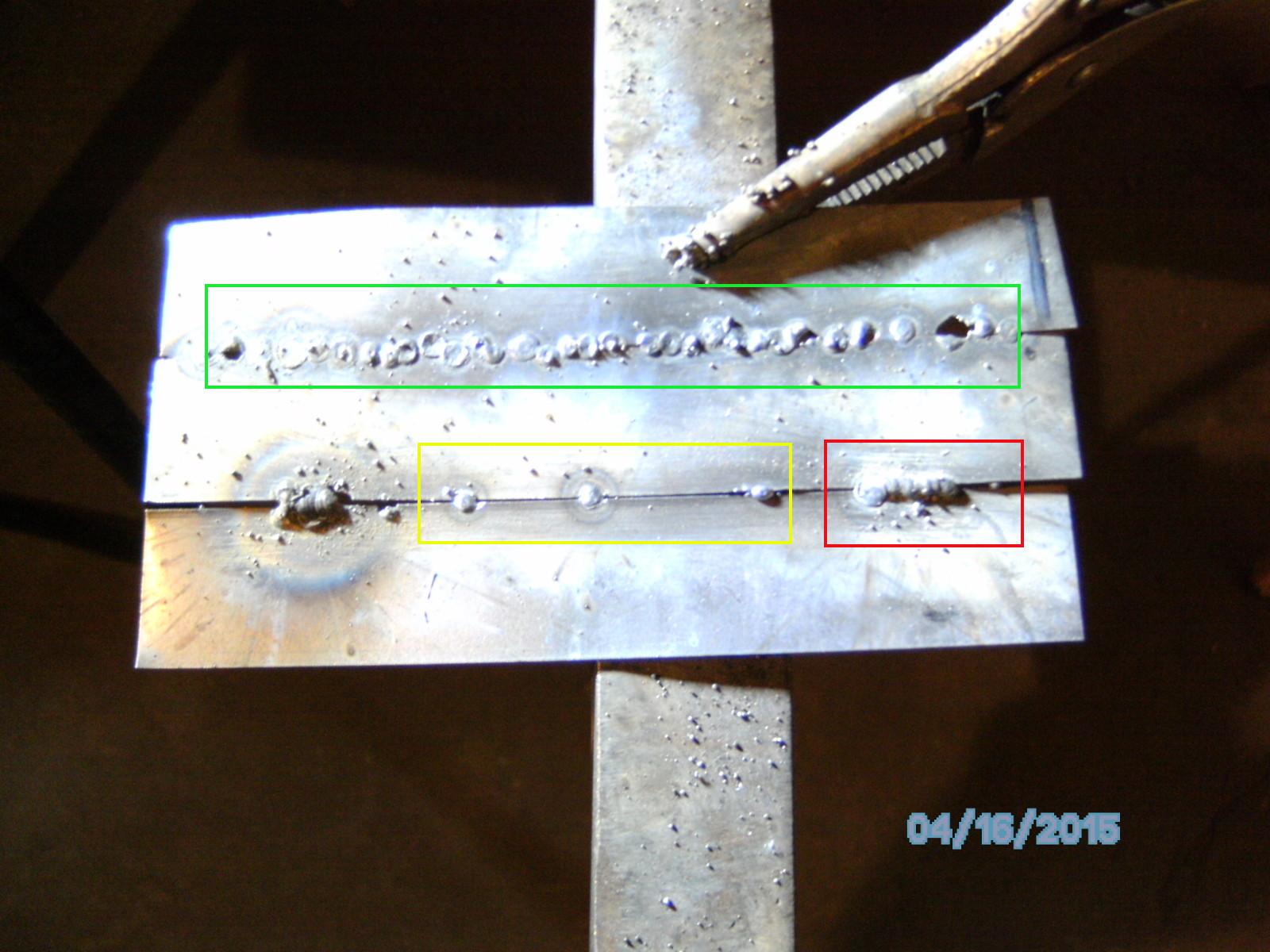

While wire feed welding sheet metal go for short bursts of welding instead of a going on a long bead.

You might be able to make it work but s it s going to be down right awful looking and you are probably going to fight with it for a.

The tables in my texts and on the machine reference gauge.

Try going for a wire of 023 inches when welding sheet metal.

Short bursts or tacks will help.